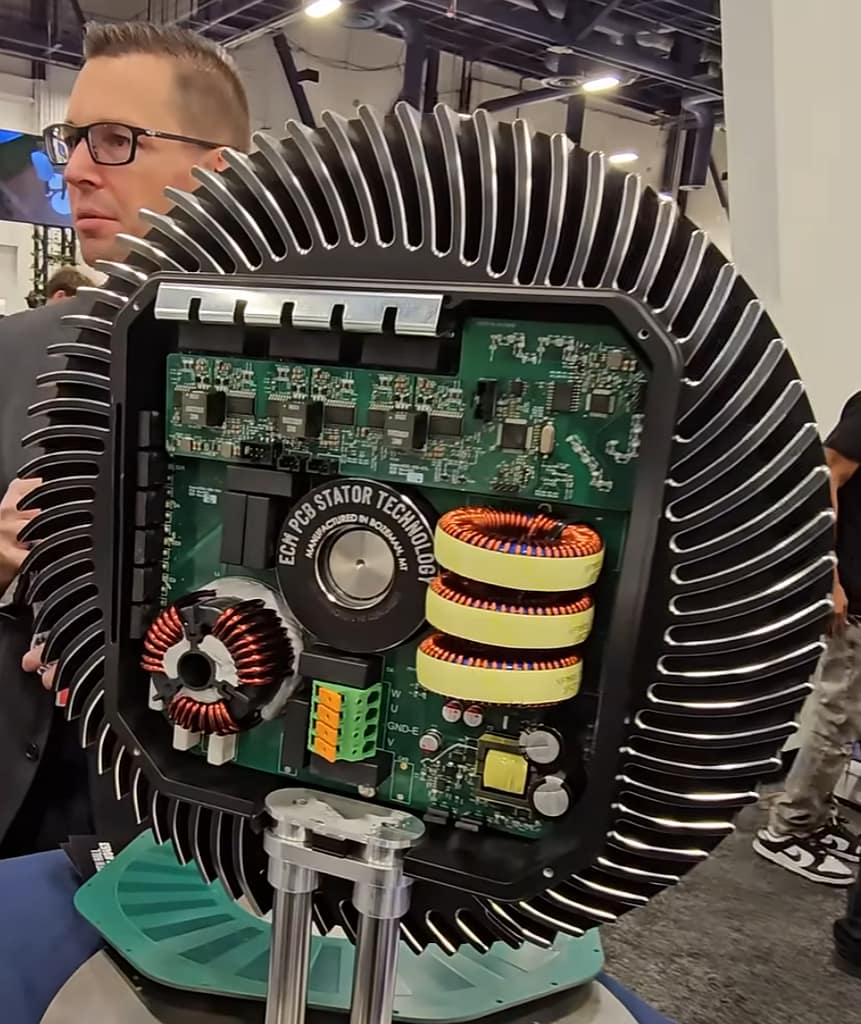

The motor technology featured in the video is a axial flux motor that uses a Printed Circuit Board (PCB) as the stator.

According to the speaker in the video:

- The motor has zero cogging because it doesn’t use any lamination steel. [00:18]

- All the windings are contained within the PCB itself. [00:27]

- The technology is also lighter, quieter and more efficient. [00:25]

This approach is different from traditional motors that use bulky copper wire windings and steel laminations. The axial flux design combined with the PCB stator results in a much thinner, flatter motor profile.

The “zero cogging” in this design refers to the elimination of cogging torque, which is the “jerky” or “notchy” feeling you get when turning a traditional permanent magnet motor by hand.

Why does it have Zero Cogging?

In a standard motor, the magnets in the rotor are naturally attracted to the steel teeth (laminations) of the stator, even when the power is off. As the rotor turns, it snaps from one tooth to the next.

Because this motor uses a PCB (Printed Circuit Board) as the stator, there is no steel for the magnets to be attracted to. This results in:

- Perfectly smooth rotation: There is no “detent” effect, allowing for ultra-precise motion.

- Reduced Noise and Vibration: Without the physical “snapping” of magnetic alignment, the motor operates almost silently.

- No Hysteresis/Core Losses: Since there is no iron core, there are no energy losses from the magnetic field constantly reversing in steel.

Applications (Addressing the “Low Torque” Concern)

While a coreless PCB stator does typically have lower peak torque than a heavy iron-core motor of the same size, it excels in applications where precision, weight, and thinness are more important than raw “stump-pulling” power. Furthermore, modern versions (like those from ECM PCB Stator Tech) use multi-layer PCBs and axial flux geometry to achieve surprisingly high torque-to-weight ratios.

Primary Applications:

- Robotics and Haptics: The zero-cogging nature makes these ideal for robotic joints and surgical robots where smooth, jitter-free movement is life-critical. It also provides excellent “back-drivability” for haptic interfaces (force feedback).

- Drones and Aerospace: The extreme weight savings (up to 70% lighter than traditional motors) and thin profile allow for longer flight times and more compact airframes.

- High-End HVAC and Fans: Because they are incredibly quiet and efficient at varying speeds, they are used in high-efficiency ceiling fans and lab equipment where acoustic noise must be minimized.

- Medical Devices: Used in pumps and scanners where electromagnetic interference (EMI) must be low and the form factor must be extremely compact.

- E-Mobility (Lightweight): While not for heavy trucks, they are used in e-bikes and lightweight scooters where the flat “pancake” shape fits perfectly inside a wheel hub or frame.

In summary: You trade raw peak torque for extreme precision, silence, and a massive reduction in weight. In many modern high-tech fields, a motor that is 1/3 the weight and perfectly smooth is a much better trade-off than a heavy, high-torque motor that vibrates.

Sources

Infinitum Electric brings its PCB stator technology to EV motors

Dual Rotor Axial Flux Permanent Magnet Motor using PCB Stator – IEEE Xplore

Dual Rotor Axial Flux Permanent Magnet Motor using PCB Stator – IEEE Xplore

Everything You Need to Know about PCB-Motor in 2025

What Makes PCB Stator Motors Ideal for Robotics and Haptics? – YouTube